TCS Battery | What Is Valve Regulated Lead Acid Battery?

1.What Is VRLA Battery

Valve Regulated Lead Acid Battery Working Principle

How to Check Lead Acid Battery

Lead Acid Battery Construction

Lead Acid Battery Maintenance&Operation

How to Inspection and Maintenance VRLA Battery?

TCS BATTERY | Professional OEM Manufacturer

2.Valve Regulated Lead Acid Battery Working Principle

PRINCIPLE

CHEMICAL REACTION IN VRLA BATTERY

PRINCIPLE

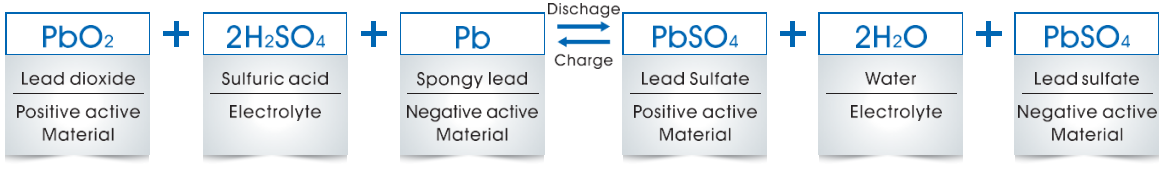

While valve regulated lead acid battery is discharged, the concentration of sulfuric acid is gradually decreased and lead sulfate is formed under the reaction between lead dioxide of positive electrode, spongy lead of negative electrode and the sulfuric acid in the electrolyte. While charging,lead sulfate in the positive and negative electrode is transformed to lead dioxide and spongy lead, and with the separation of sulfuric ions, the concentration of sulfuric acid will increase. During the last charging period of traditional valve regulated lead–acid , water is consumed by the reaction of hydrogen evolution. So it requires compensation of water.

With the application of moist spongy lead, it promptly reacts with oxygen, which effectively controls the decrease of water. It is same as the traditional VRLA batteries from the beginning of charge to before the final stage, but when it is over-charged and in the last period of charge, the electric power will start to decompose water, negative electrode will be in discharge condition because oxygen from the positive plate reacts with spongy lead of negative plate and sulfuric acid of electrolyte. That restrains the hydrogen evolution on the negative plates. The part of negative electrode in discharge condition will transform to spongy lead while charging. The quantity of spongy lead formed from charging equals to the quantity of sulfate lead as the result of absorbing the oxygen from positive electrode, which keeps the balance of negative electrode, and also make it possible to seal valve regulated lead acid battery

CHEMICAL REACTION IN VRLA BATTERY

3.How to Check Lead Acid Battery

| Monthly check | |||

| What to inspect | Method | Stand spec | Measures in case of irregularity |

| Total battery voltage during float charge | Measure total voltage by voltmeter | Float charge voltage* number of batteries | Adjusted to the float charge voltage number of batteries |

| Half year check | |||

| Total battery voltage during float charge | Measure total battery voltage by voltmeter of class 0.5 or better | Total battery voltage shall be product of float charge voltage with battery quanting | Adjust if the voltage value is outside standard |

| Individual battery voltage during float charge | Measure total battery voltage by voltmeter of lass 0.5 or better | Within 2.25+0.1V/cell | Contact us for remedy; Any lead acid battery showing errors greater than permissible value shall be repaired or replaced |

| Appearance | Check for damage o r leakage at container and cover | Replaced by electric tank or roof without damage or leakage acid | If leakage is found verify the cause, for container and cover having cracks, vrla battery shall be replaced |

| Check for contamination by dust, etc | Battery no dust pollution | If contaminated, clean with wet cloth. | |

| Battery holder Plate Connecting cable Termination rust | Perform cleaning, rust preventive treatment, painting of touch up. | ||

| One-year inspection (following inspection shall be added to six-months inspection) | |||

| Connecting parts | Tighten bolts and nuts | Checking (connecting screw stud books and torque) | |

| Monthly check | |||

| What to inspect | Method | Stand spec | Measures in case of irregularity |

| Total battery voltage during float charge | Measure total voltage by voltmeter | Float charge voltage* number of batteries | Adjusted to the float charge voltage number of batteries |

| Half year check | |||

| Total battery voltage during float charge | Measure total battery voltage by voltmeter of class 0.5 or better | Total battery voltage shall be product of float charge voltage with battery quanting | Adjust if the voltage value is outside standard |

| Individual battery voltage during float charge | Measure total battery voltage by voltmeter of lass 0.5 or better | Within 2.25+0.1V/cell | Contact us for remedy; Any lead acid battery showing errors greater than permissible value shall be repaired or replaced |

| Appearance | Check for damage o r leakage at container and cover | Replaced by electric tank or roof without damage or leakage acid | If leakage is found verify the cause, for container and cover having cracks, vrla battery shall be replaced |

| Check for contamination by dust, etc | Battery no dust pollution | If contaminated, clean with wet cloth. | |

| Battery holder Plate Connecting cable Termination rust | Perform cleaning, rust preventive treatment, painting of touch up. | ||

| One-year inspection (following inspection shall be added to six-months inspection) | |||

| Connecting parts | Tighten bolts and nuts | Checking (connecting screw stud books and torque) | |

4.Lead Acid Battery Construction

Safety valve

Synthesized with EPDM rubber and Teflon, the function of safety valve is to release gas when the internal pressure rises abnormally which can prevent water losses and protect TCS vlra battery from explosion by over-pressure and over-heat.

Electrolyte

Electrolyte is compounded with sulfuric acid, deionized water or distilled water. It takes part in the electrochemical reaction and plays as the medium of positive and negative ions in liquid and temperature between plates.

Grid

To collect and transfer current, grid-shape alloy (PB-CA-SN) plays a part of supporting active materials and distributing current in active materials equally.

Container&cover

Battery case includes container and cover. Container is used to hold positive and negative plates and electrolyte. Preventing impurities entering cells, cover also can avoid acid leakage and venting. Containing all materials relating charge and discharge, ABS and PP material are . chosen as battery case because of their well performance in insulativity, mechanical strength, anticorrosion and heat resistance.

Separator

Separator in VRLA battery should consist of porous mass and adsorb massive electrolyte to make sure the free movement of electrolyte, positive and negative ions. As the carrier of electrolyte, separator also should prevent the short circuit between positive and negative plates. Providing the shortest distance for negative and positive electrode,separator prevents lead paste to be damaged and dropped, and prevents the contact between the cast and electrode even when the active materials is off the plates, It also can stop the spread and shift of hazardous substance. Glass fiber, as the normal and frequent choice, is characterized with strong adsorbability, tiny aperture, high porosity, large pore area, high mechanical strength, strong resistance to acid corrosion and chemical oxidizing.

5.Charging Characteristics

► Floating charge voltage must be kept at a appropriate level to compensate self-discharge in batteries, which can keep the lead acid battery in a fully charged condition at all times. The optimum floating charge voltage for the battery is 2.25-2.30V per cell under normal temperature{25 C), When the electric power supply is not stable, the equalizing charge voltage for the battery is 2.40-2.50V per cell under normal temperature(25 C). But long time equalised charge should be avoided and less than 24 hours.

► The chart as below shows the charging characteristics at a constant current (0.1CA) and a constant voltage(2.23V/- cell) after discharge of 50% and 100% of the 10HR rated capacity. The time of fully charge varies by the discharge level, initial charge current and temperature. It will be recover 100% discharge capacity in 24 hours, if charging a fully discharging lead acid battery with constant current and constant voltage of 0.1 CA and 2.23V respectively at 25C. The initial charge current of battery is 0.1 VA-0.3CA.

6. VRLA Battery Life

► The valve regulated lead acid battery life of floating charge is influenced by discharge frequency, discharge depth, float charge voltage and service environment. The gas absorption mechanism described preciously can explain that the negative plates absorb the gas the generate in the battery and compound water at normal float charge voltage.Therefore, capacity will not decrease due to electrolyte depletion.

► Proper float charge voltage is necessary, because corrosion speed will be accelerated as the temperature rises that may shorter valve regulated lead acid battery’s life. Also the higher the charge current, the faster the corrosion. Therefore, the float charge voltage should always be set at 2.25V/cell, using a valve regulated lead acid battery charger with voltage accuracy of 2% or better.

7.Lead Acid Battery Maintenance&Operation

► Battery Storage:

The vrla battery is delivered in a fully charged condition. Please note the points before installation as below:

A. Ignitable gases may be generated from the storage battery. Provide sufficient ventilation and keep the vrla battery away from the sparks and naked flame.

B. Please check for any damage to the packages after arrival, then unpack carefully to avoid damage to the battery.

C. Unpacking at the installation location, please take out the battery by supporting the bottom instead of lifting the terminals. Attention that sealant may be disrupted if the battery is moved with force on the terminals.

D. After unpacking, check the quantity of the accessories and the exterior.

► Inspection:

A. After verifying no abnormality in the vrla battery, install it on the prescribed location (e.g. cubicle of battery stand)

B. If the agm battery is to be accommodated in a cubicle, place it at the lowest place of the cubicle whenever it is practicable. Keep at least 15mm distance between the lead acid batteries.

C. Always avoid installing the battery close to a heat source (such as a transformer)

D. Since s storage vrla battery may generate ignitable gases, avoid installing close to an item that produces sparks (such as switch fuses).

E. Before making connections, polish the battery terminal to bright metal.

F. When a multiple number of the batteries are used, first connect the inner-battery in a correct manner, and then connect the battery to the charger or the load. In these cases, the positive”) of the storage battery should be securely connected to the positive(+) terminal of the charger or the load, and negative(-) to negative(-), Damage to the charger may be caused by the incorrect connection between lead acid battery and charger. Make sure all connections are correct. The tightening torque for each connecting bolt and nut shall be in accordance with the below chart.

How to Inspection and Maintenance VRLA Battery?

TCS BATTERY | Professional OEM Manufacturer